COMPANY

COMPANY POLICY

COMPETENCE AND RELIABILITY

As a deep drilling specialist, the company is now a competent partner for more than 1,000 renowned customers from the machine tool industry, mechanical and plant engineering, the chemical industry and mold making. We feel at home in metalworking.

With a highly qualified and motivated team, workpieces are processed quickly, precisely and at favorable conditions. Our customers particularly appreciate our experience with complex workpieces made of high-quality, difficult-to-machine materials.

Our customers can also be offered time- and cost-saving complete production, which can include deep drilling, turning, milling and material procurement as well as a variety of further processing.

The DIN ISO 9001 certified quality management system, which has been in place since 2002, supports customer-oriented and modern production.

Competence and reliability have a high priority, documented by customers who have been associated with the company for several

decades. We are committed to our customers, our environment and our employees and attach great importance to compliance with existing specifications

and laws while constantly developing our company further.

Company history

History

A FAMILY BUSINESS WITH A LONG TRADITION

The more than 125-year history of this Swabian family-owned company combines tradition, modernity and high-tech. It has thus successfully joined the ranks of traditional companies that are actively shaping the future.

This history began in 1882 with the founding of the “Robert Gutekunst Fabrik für blanke Schrauben” (Robert Gutekunst Factory for Bare Screws) based in Owen unter Teck.

The production assortment ranged from screws, nuts and turned parts to profile material. After the war, production was moved to Kirchheim unter Teck.

Entry into deep drilling technology

The continuously growing operations and the owner family, which had become larger over the decades, led to a division of the companies into the Kirchheim unter Teck and Römerstein-Zainingen operations in April 1979 as an independent operation with sole responsibility.

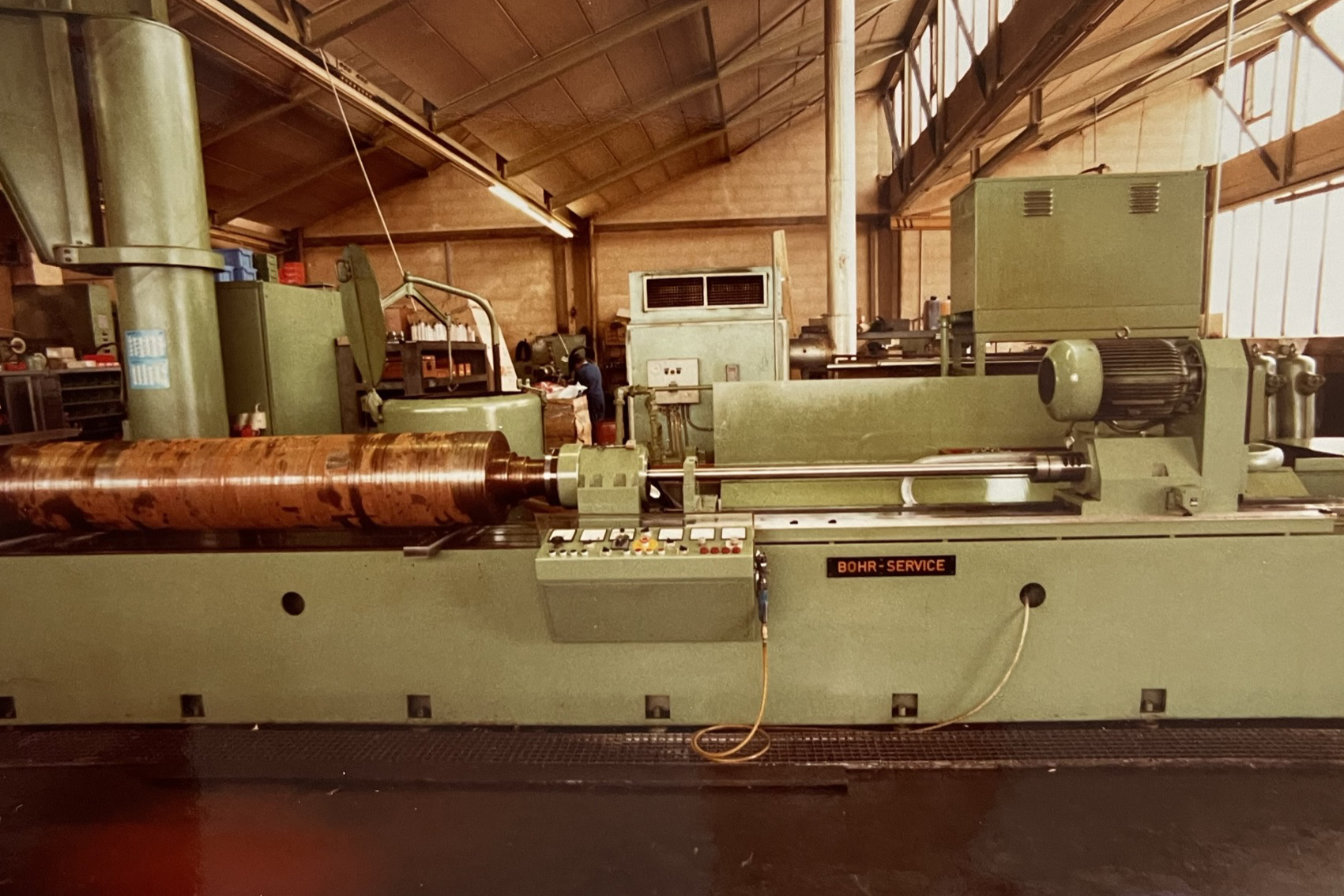

Originally founded in 1958 as a turning shop and agricultural machinery workshop by Heinrich Class, the company was expanded more and more intensively into a deep drilling shop. The initial product range was successfully expanded and since 1979 the technical fields of deep drilling and hydraulic production gained a new importance.

Today, deep drilling is the dominant area of the company.

Modernization

In 1983, ROBERT GUTEKUNST OHG purchased a 3,000 sqm building site to the east of the leased factory premises for future expansion.

Additional CNC machining centers and other machines were purchased for modernization and new employees were hired.

Expansion

In 1988, the previously leased factory building and site with approx. 4,200 m² was purchased and a new, modern factory building with a two-story office wing and a 12 m high hall with almost 600 m² for the deep drilling shop was built, which was bursting at the seams. The new factory building was completed at the end of 1990.

Thanks to the continuous acquisition of new machinery and equipment, cranes and lifting equipment, the company is at a level that allows for more technically advanced work.

New warehouse and production hall

Succession and generation change

THE BEGINNING OF A NEW EPOCH

The Gutekunst family and Mr Dieterich have handed over their family business, Gutekunst GmbH, to new hands as of 14 September 2018. As part of a succession plan, the company has been handed over to the Egner family. As a result, the tradition of an owner-managed family business is being preserved, while at the same time a generational change in the management of the company has been achieved.

Philipp Egner, an internationally educated young manager, has taken over the operational management of the company as managing partner. His father, Dr Manfred Egner, and Mr Robert Gutekunst will continue to provide advice and support.

Mr Wilfried Dieterich will also remain with the company as Technical Director and member of the Management Board.

Entry into new technology

We are currently looking for:

We train

Certificates

Under the following link you will findthese certificates available for download:

ISO 9001:2015 DE

ISO 9001:2015 EN